The hydraulic hose often cracks during use. Now let’s analyze the common types of rubber hose rupture and their causes.

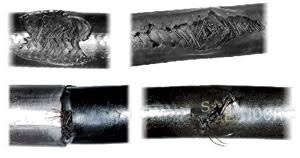

1 The hose is broken at one or more places, and the reason for this phenomenon is that the system pressure is too high, which exceeds the pressure resistance of the hose. If the system pressure meets the requirements, the actual pressure resistance of the hose used should be checked to meet the design requirements.

2 Torsion at the rupture of the hose This phenomenon is caused by excessive twisting of the hose during installation or use. After the hose is twisted, the structure of the reinforcing layer changes, the gap between the braided and wound wires increases, and the compressive strength of the hose is lowered, and the hose is easily broken under the action of high pressure. Therefore, during the process of using or storing the hose, the hose should not be subjected to the torsional moment. When installing the hose, the axes of the two joints should be placed on the same plane as much as possible to prevent the hose from being twisted during use.

3 The wire is curled at the rupture of the hose. The obvious necking phenomenon causes this phenomenon because the hose is subjected to excessive tensile deformation, and the layers are separated to reduce the compressive strength. The hose will shrink or elongate in the longitudinal direction under the action of high pressure. The general expansion and contraction amount is +2%~-4% under normal conditions. If the hose is selected too short during installation, it will be greatly stretched during operation, and if it is severe, it will be broken or loose. If the span of the hose is too large, the weight of the hose and the weight of the hose will also be This will give the hose a large tensile force, which can also occur in severe cases. Therefore, appropriate solutions should be adopted depending on the specific situation. If it is too tight during installation, replace the lengthened new tube; if the span is too large, add the intermediate support clip.

1. The hydraulic pipe is stored in a relaxed state as much as possible. Generally, the hose with an inner diameter of 76 mm or less can be stored in coils.

1. The hydraulic pipe is stored in a relaxed state as much as possible. Generally, the hose with an inner diameter of 76 mm or less can be stored in coils. 4. During the storage of the hydraulic pipe, it should not exceed 2 years, and should be used first before the storeer to prevent the quality of the hose from being affected due to long storage.

4. During the storage of the hydraulic pipe, it should not exceed 2 years, and should be used first before the storeer to prevent the quality of the hose from being affected due to long storage. 8. When storing the hydraulic pipes, they should be placed according to different specifications. Do not mix and stack, and hang the management card.

8. When storing the hydraulic pipes, they should be placed according to different specifications. Do not mix and stack, and hang the management card.