SAE 100 R3 textile reinforced hydraulic hose is suitable for delivering petroleum or water-based hydraulic fluids. It is mainly used in low pressure conditions and it is also used in pneumatic applications. It is composed of three parts: tube, reinforcement and cover. The tube is made from high quality oil resistant synthetic rubber, and it doesn’t react with petroleum or water-based hydraulic fluids. The reinforcement is made from two layers of braided textile, making the hose lightweight and flexible. The hose is easy to operate as a result. The cover is made from high quality abrasion, corrosion, weather and oil resistant synthetic rubber, making the hose have longer service life.

Recommended For: Low-pressure hydraulic lines. Meets or exceeds the requirements of SAE100 R3 AT.

Tube:Black,oil resistant,synthetic rubber.

Reinforcement: Two braids fiber layer

Cover:Black, oil,abrasion and weather resistant, thin synthetic rubber

Temperature Range: -40℉ to +250℉ (-40℃ to +121℃)

Products Application :

Hydraulic hose SAE 100R3 can be used for hydraulic oil delivering ,and some low oil machine.

Raw Material:

imported rubber materials LG NBR rubber from South Korea,

imported BELKTA steel wire with high tensile strength2750Mpa from Belgium.

Good quality materials make our hydraulic hose steady performance ,

good decentrality, excellent oil resistance.

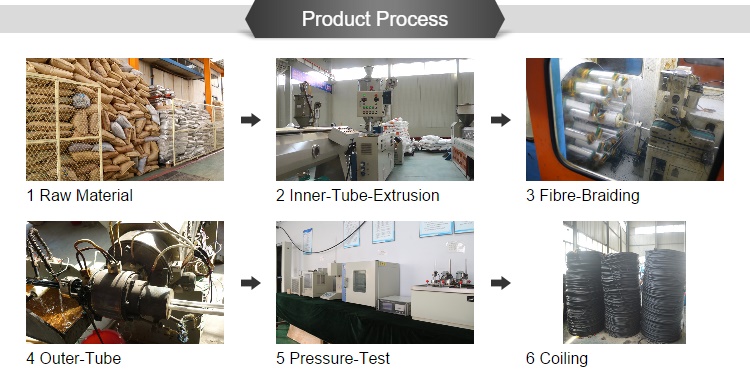

Factory Workshop:

Our factory introduce advanced technology and equipment to make the bets quality hydraulic hose.

Our bunching Machine is SEJIN MACHINE from Korea.The advantages of the machine are high accuracy ,high consistency,suspension difference < 70MM,the international standard is 120MM.

We use Mitsubishi electric control braiding machine .We use the machine can get high accuracy data collection, real-time braiding angle monitoring and correction.

Laboratory:

Laboratory:

Our factory has strong quality control team, we set up advanced laboratory.

Before the mass production, we test each batch of raw material

After the production, we test each hose to guarantee a 100% qualification.

Each hose tested at 2 times of working pressure.

We do everything possible to supply good quality goods for our customer.

After finishing the Hydraulic Hose production, we will pack the hose. In general, the packing will

use woven bag and plastic film. Special packing is available according to customers’ requirements.